Traceability

- 2″ Fig 1502 Male X Female with 3/4″ or 1″ 3 Fig 1502

- Male X Female with 2″ Orifice.

- Standard service is used up to 15,000 psi & tested at 22,000 psi.

- H2S service is used up to 10,000 psi & tested at 15,000 psi.

- Hammer Union End Connection.

- Forged alloy steel body, stainless steel & tungsten carbide parts.

- Parts are interchangeable with major brands.

- Suitable for a broad range of applications including wellheads, Well testing, Stream injections, choke and kill manifolds and well clean operations etc.

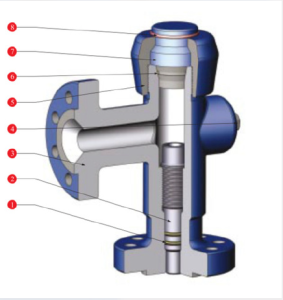

API 6A Choke Valve

Features: Long life and Low maintenance Body to bonnet contact behind the O-Ring Seal eliminates bonnet seal extrusion. A Locking device is set on stem. Ideal for many flow regulating services and easily convertible to a Positive Choke. The Stem of adjustable Choke are made of high strength alloy steel. The materials have the feature of abrasion, erosion resistance and reliable serviceability. The Valve and Seat can be removed by hand, without special tools, without removal the valve body from the line, by simply removing the bonnet.

Choke VALVE

Features: Body to bonnet connect behind the O-Ring seal eliminates bonnet seal extrusion. The Bean of positive choke of ceramic or hard alloy steel. Both have the feature of abrasion resistance, erosion resistance and reliable serviceability. Flow Bean chamfers are available from 2/64″ to 64/64″. in 1/64″ increments for precise regulations of flow rate. The Choke Beam may be dismantled quickly for change of beam.